We offer several technics several technics to improve medical stainless steel so that it answers to all medical standards in application in the surgical and medical sector. Among these technics, electrolytic polishing is one of the most efficient in protecting the part against corrosion. Discover the results of this technic and other processes that we apply.

Medical Stainless Steel

Stainless steel is privileged in the medical domain for its weak roughness, easy to work on, it also resists better to corrosion.

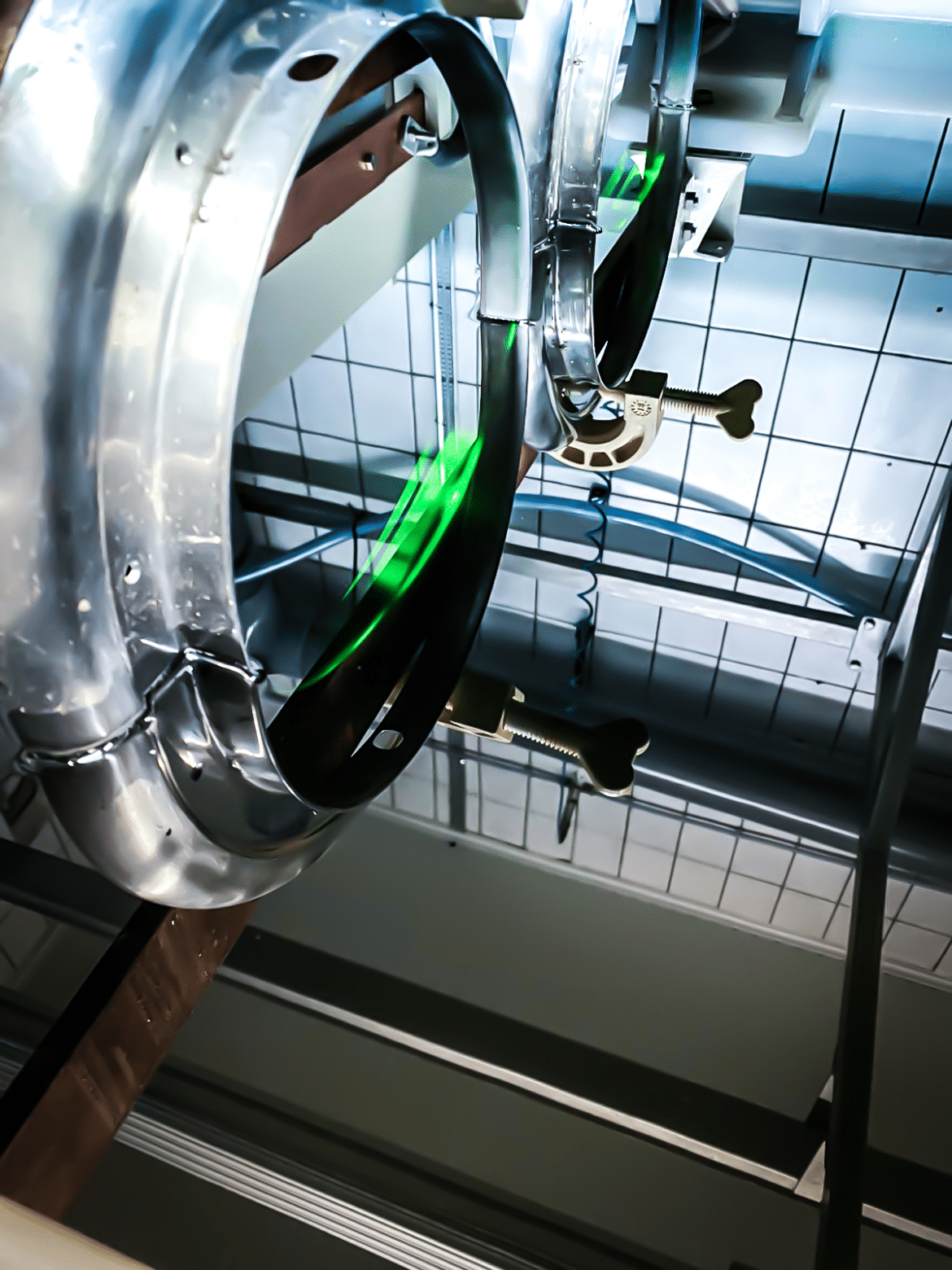

For medical stainless steel, we will use an electrolytic polishing process. This technic consists of dissolving the superficial layer of the part to bring up the chromium layer to the surface through an anodic separation. This process is the opposite to galvanisation or chromium plating, where on the contrary a metal layer is added to the metal part.

For this process, we temper the stainless-steel part in a high concentration electrolytic bath with two electrodes. The part treated is after linked to an anode (side up) and continuous power input is applied, the electric intensity is variable according to the required result. The different parameters will have an impact on the quality of the final stainless-steel medical part, especially on the surface shine and its (RA) roughness coefficiency. Preparation on the surface to be treated is of extreme importance for the final result. The roughness coefficiency will never be void but the better the preparation the lower the RA will be.

Electrolytic or electro-polishing can be used to treat very complex geometrical surfaces. This technic will enable a reduction in machining grooves, it will also avoid any new deposits that could be on stainless-steel, thanks to a better surface that is more resistant to corrosion. This is an efficient technic because the surface will be perfectly homogenous and more resistant to wear and corrosion.

The standards concerned

The treatment system must comply with the ISO standards 13485 and to the polishing standards for stainless-steel ASTM B912. Our system has a quality certification ISO 13485 and all our teams are trained for the specifications that are required for these two standards.

The ISO standard 13485 defines the requirements for Quality Management System concerning the medical requirements. To be certified ISO 13485, a production system must be set up with specific procedures to ensure product safety and quality during the full cycle of production.

Concerning the polishing standards stainless-steel ASTM B912, it defines a quality standard level in polishing process of stainless-steel. To comply with this standard, it is necessary to use specific measures such as: trials (salt spray tests, copper sulphate).

Treatment of austenitic or martensitic stainless-steel for the medical industry

Medical or surgical stainless-steel is a stainless-steel material which is made up of a minimum of 13% chromium and 0.2% carbon. The chromium will have a role in improving the metal resistance to corrosion. Nickle could also be added, but all stainless-steel in the medical industry does not contain nickel due to its possible allergic reactions so there is no guarantee.

There are several types of medical stainless-steel: austenitic (without heat treatment) stainless-steel type 316 and martensitic (with heat treatment) type 420 and 440.

Depending on its future use, medical instruments must be in stainless-steel that is ductile material, it must have a big capacity to deforming without breaking, so martensitic stainless-steel is our choice. For implants austenitic stainless-steel without copper or additives titanium, cobalt alloys are privileged. Furthermore, the use of austenitic stainless-steel must comply with the reglementary standards for medical implants.

We also carry out heat treatment on the austenitic or martensitic stainless-steel by electrolytic polishing process in compliance with the ISO 13485 and ASTM B912 standards.